MIS Software solutions

The industrial printing of labels and packaging can be quite complex. You need a complete MIS software solution to master every order, from optimizing printing orders and calculating waste to managing the use of materials and shipping costs.

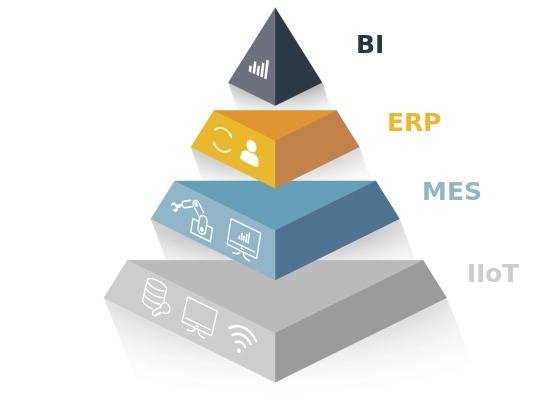

The CERM MIS Software covers the three upper levels of your company’s management, manufacturing and monitoring tools, and converts them into a fully integrated and interactive framework.

Business Intelligence

Collects all captured business data and helps to interpret your printing company’s performances by converting the collected data into strategic and user-friendly reports.

Enterprise Resource Planning

Streamlines the most important management functions of your printing company in one platform.

Manufacturing Execution System

Includes all operating systems that control and monitor the entire production process.

Industrial Internet of Things

Represents the registration of all possible data within your printing company and its technological environment.

Our CERM MIS is tailored to the Label and Packaging Industry

Improve your workflow even further with these extensions for a more comprehensive MIS

Discover our

Compatibility for workflow efficiency

Discover our

On our way to you for a free demo

Our CERM MIS Software is one of the most reliable there is in the world. We wouldn’t want you to take our word for it. Just see for yourself

Discover our

Book a testdrive and convince yourself

Take CERM MIS for a test drive and find out how our software makes the difference. It allows you to test our CERM MIS Software during a trial period before you commit.

Discover our